Follow the making of a bowl

The bowls are thrown on the potters wheel, then put on the shelves to dry o

| |

When the bowls are 'leather hard', the bases are trimmed.

We then brand them with our mark.

Then back to the shelves to dry completely.

l

| |

When they are completely dry the are loaded for the bisque (first firing). This firing takes about 12 hours and turns the pot into a ceramic. The bisque kiln fires to Cone 04, or 1050 degrees Celsius. The kiln is computer controlled.

They can now be easily handled and are ready for glazing.

| |

Next the bowls are dipped in wax to stop the glaze from sticking to the base, and then in turn to stop the pot from sticking to the kiln shelves

| |

The pots are dipped in a base glaze, then sprayed with a top glaze

.

| |

The pots are now glazed and ready for firing.

| |

Next the kiln is loaded for the glaze firing.

| |

.

The cones are made of different types of clay that bend at different temperatures. The one on the right is Cone 10, when it bends the kiln will have reached 1300 degrees Celsius which will take approximately 12 hours.

All fired and ready for unloading.

| |

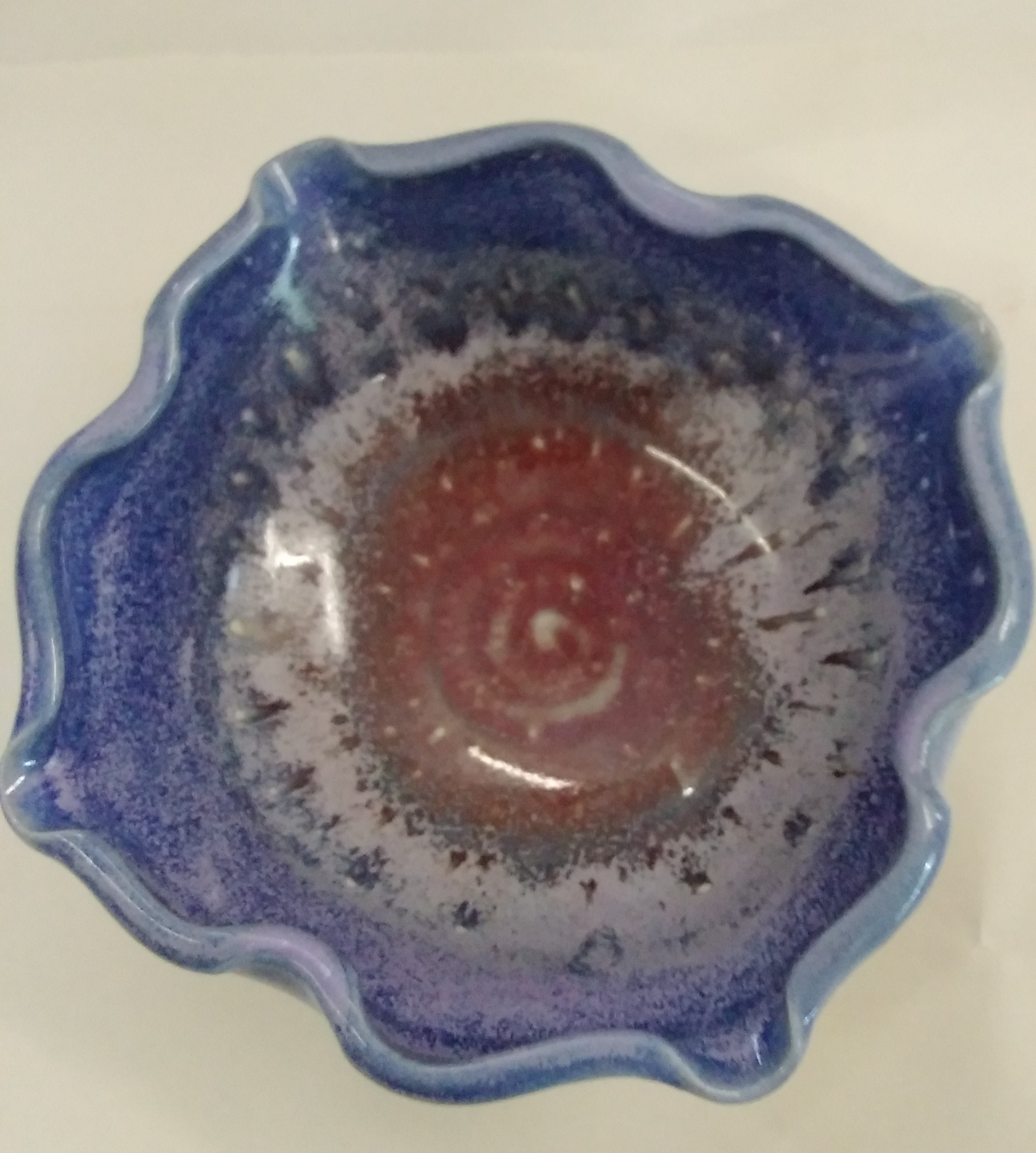

The Finished product